rockwell hardness test ball indenter|hardness testing ball indenters : agency Vickers Diamond Indenter - Zwick: 912: Vickers Diamond indenter in Rockwell . Aprenda a tocar a cifra de Crazy (Gnarls Barkley) no Cifra Club. (Feat. Joe Budden) / [Joe Budden] / Yo. you ever wake up feeling unusual? / I mean, it's funny what a bad mood'll do / I know some might say I'm not suitable / or ma

{plog:ftitle_list}

web5 de ago. de 2023 · Caduca el: 31-12-2023. Último control: hace 2 días. ¿Jokerbet trabaja con codigo promocional? Page Contents. 1 ¿Jokerbet trabaja con codigo .

Gilmore Diamond Tools’ manufactures diamond indenters and penetrators for all makes and models of Rockwell hardness testing machines – as well as custom indenters for use in difficult testing situations.

Gilmore Diamond manufactures many accessories specifically designed for .Vickers Diamond Indenter - Zwick: 912: Vickers Diamond indenter in Rockwell .Gilmore Diamond Tools manufactures Rockwell Hardness Testing products, .

Indenters. According to the latest standards, there are changes to both Rockwell and Brinell scales. The test method for Rockwell testing (ASTM E-18-08a) only allows the use of .

We offer a wide range of ball indenters as well as loose balls and caps for Brinell and Rockwell hardness testing. Our ball indenters are available in Tungsten, Carbide or Steel. They come .Manufactured in the USA, and calibrated and certified in our ISO/IEC 17025 accredited standardization laboratory to meet all ASTM standards. Our ball intenders are available in carbide or steel for rockwell hardness testing. Also .Hardness tests can be defined as forcing an hardness testing indenter of a specified size, shape, and material into the surface of a test piece to obtain a hardness value. . 9100405 - Rockwell indenter 1/16" WC ball with 4 spare .

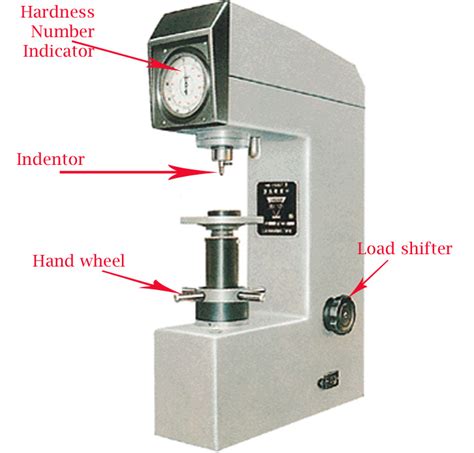

See a Rockwell hardness testing solution in action. . The Rockwell Hardness Test uses a diamond cone or hardened steel ball to indent the material being tested. Each time a test is performed, two loads are applied to the sample. .Test hardness right on your production floor. Unlike benchtop testers, these portable ones don’t require you to move large or hard-to-access parts. They use an indenter to measure the hardness of aluminum, brass, and steel. These testers can be used at any angle without affecting accuracy.. For heat-treated material harder than Rockwell C20, use the optional C-scale .

If a ball indenter is used, then. Rockwell Hardness Number = 130 - (H/0.002) Where 'H' is in mm. . What is the principle of Rockwell hardness test? Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material.

Suntec's Brinell hardness test ball indenters are essential for accurate and reliable hardness measurements. Trust our high-quality indenters to provide precise impressions, ensuring consistent and dependable results in your Brinell hardness testing process and material characterization applications. . Rockwell Type Diamond Indenter Select .Our ball intenders are available in carbide or steel for rockwell hardness testing. Also available as a ball indenter assembly. . Rockwell Type Ball Indenter quantity. Add to cart. Add to quote. SKU: N/A Category: Indenters. Related products. Rockwell Type Diamond Indenter Select options This product has multiple variants. The options may be .Mitutoyo Steel Ball Indenter. These steel ball indenters are for use with the Mitutoyo Rockwell and Rockwell Superficial type hardness testing machines. Select from the options below: 1/16" Diameter Steel Ball Indenter (64HAA118) 1/8" Diameter Steel Ball Indenter (64HAA121) 1/4" Diameter Steel Ball Indender (64HAA123) 1/2" Diameter Steel Ball .The standard Rockwell hardness scales, along with information on the type of indenter, the magnitude of the major load, and also typical applications for each of the hardness scales, as defined by ASTM standard E18 (1984), are presented in Table 1.In all cases, the minor load is 10 N.It is clear from Table 1 that the hardness of a wide range of materials can be estimated .

Rockwell hardness testing can determine the hardness of most metals, alloys and plastics. . (100 Rockwell points) penetration, the HRB and other regular scales use a ball indenter because they test softer materials and have a maximum depth of 0.26 millimeter (130 Rockwell points). As the Rockwell test gained popularity, the need to test thin .

rockwell hardness testing procedures

Cone indenter: 120°

For more information about Rockwell Ball Scale Indenters, contact our knowledgeable sales engineers by calling 1-847-577-3980 or emailing [email protected]. . Hardness Testing Indenters > Wilson Brand Indenters > Rockwell Indenters > . Rockwell Diamond Indenter Brand. Wilson (24) Price. The combination of indenter and test force make up the Rockwell scale. These combinations make up 30 different scales and are expressed as the actual hardness number followed by the letters HR and then the respective scale. A recorded hardness number of 63HRC signifies a hardness of 63 on the Rockwell C scale..00 - 0.00 (18) 0.01 - 0.00 (3) 0.01 .II. What Distinguishes the Rockwell Method? The distinguishing factors of a Rockwell method from other methods include Type of Indenter – The Rockwell method indenters include a hardened steel ball with four different diameters and a conical diamond indenter. These indenters are unique to the Rockwell hardness test alone. For the Rockwell scales that use a ball indenter, either a steel or tungsten carbide (WC) ball indenter is permitted to be used in the test method standards of ASTM International and International Organization for Standardization (ISO). However, significant differences occur in Rockwell hardness tests depending on whether a steel or WC ball is .

Rockwell hardness test, as a measure of the resistance of a material to localized plastic deformation, is a valuable and widely used mechanical test. However, the accuracy of Rockwell hardness measurement is still in question. The indenter, including both the spheroconical diamond indenter and ball indenter, is a major contributor to Rockwell .

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for . The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test parameters. Advantages of Rockwell Hardness Test. Typically, the .For the Rockwell Hardness Test, the Indenter is a Small Steel Ball (HRB) or a diamond cone (HRC) Hardness greater than 650 HB can not be measured with the Brinell Scale setup. . Brinell Hardness (HB)-3000Kg-10 mm Ball: Rockwell Hardness (HRC)-150Kg Brale: Rockwell (HRB)- 100Kg 1/16″ Ball . The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter into the surface of a material. Hardness is evaluated by measuring the difference in depth of the indentation as the force on the .

Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. . The various indenter types combined with a range of test loads form a matrix of Rockwell hardness scales that are applicable to a wide variety of materials. . (1/16 inch) diameter tungsten-carbide ball and the major .An indenter with a hard metal ball or a cone/diamond pyramid is pressed vertically into the surface of the test specimen resting on a solid support. The test load is applied impact-free with . Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method . Type of Indenter Diameter in case of Ball: Minor Load: Major Load: Typical use: HRA: Spherical diamond: 98.07 N (10 kgf) 588.4 N (60 kgf) Cemented carbides, thin steel, and shallow case hardened steel: HRB: Ball, 1.588 mm (1/16 inch)

ROCKWELL HARDNESS TESTING MACHINES TEST EQUIPMENT HR-300/400/500 SERIES AND SEISMOMETERS. Rockwell Hardness Testing Machines to suit . Diamond indenter For Rockwell and Rockwell superficial testing Display mounting bracket Hardness test block 30-35HRC Ball indenter 1/16" Tungsten carbide ball (ø1.5875) Power cord For AC115V .Diamond indenter For Rockwell and Rockwell superficial testing Display mounting bracket Hardness test block 30-35HRC Ball indenter 1/16" Tungsten carbide ball (ø1.5875) Power cord For AC115V Hardness test block 60-65HRC Flat anvil ø64 mm Accessory Box Hardness test block 90-95HRBThe Brinell hardness test uses a spherical indenter, while the Rockwell hardness test uses either a diamond cone or steel ball indenter. . The diamond cone or steel ball indenter used in the Rockwell hardness test can cause damage to the surface of the material being tested. This can be a limitation in applications where surface quality is .The Rockwell hardness test is a indentation hardness test in which a diamond cone having an included angle of 120o and radius of curvature at the tip of 0.2mm, or a hardened steel or hard metal ball having a diameter of 1.5875mm for B, F, G and all 'T' scales or 3.175 mm for E, H and K scales are used.The indenter is forced into the surface of a test piece in two steps, initially .

Bharat Mechnocrat - Offering Silver 1/16" Ball Indenter for Rockwell Hardness Tester, For Industrial, Model Name/Number: Hrb at Rs 2500/piece in Kolkata, West Bengal. Also find Diamond Indenter price list | ID: 25802750573 . Suitable for HRB Hardness Test. View All Details. Get Latest Price. Bharat Mechnocrat.

rockwell hardness testing balls

Resultado da 17 Context. Copy Link. cookiecrumble FedoraHat 1yr ago #192814 Edited 1yr ago. The video where you can see the torture and execution of a man, .

rockwell hardness test ball indenter|hardness testing ball indenters